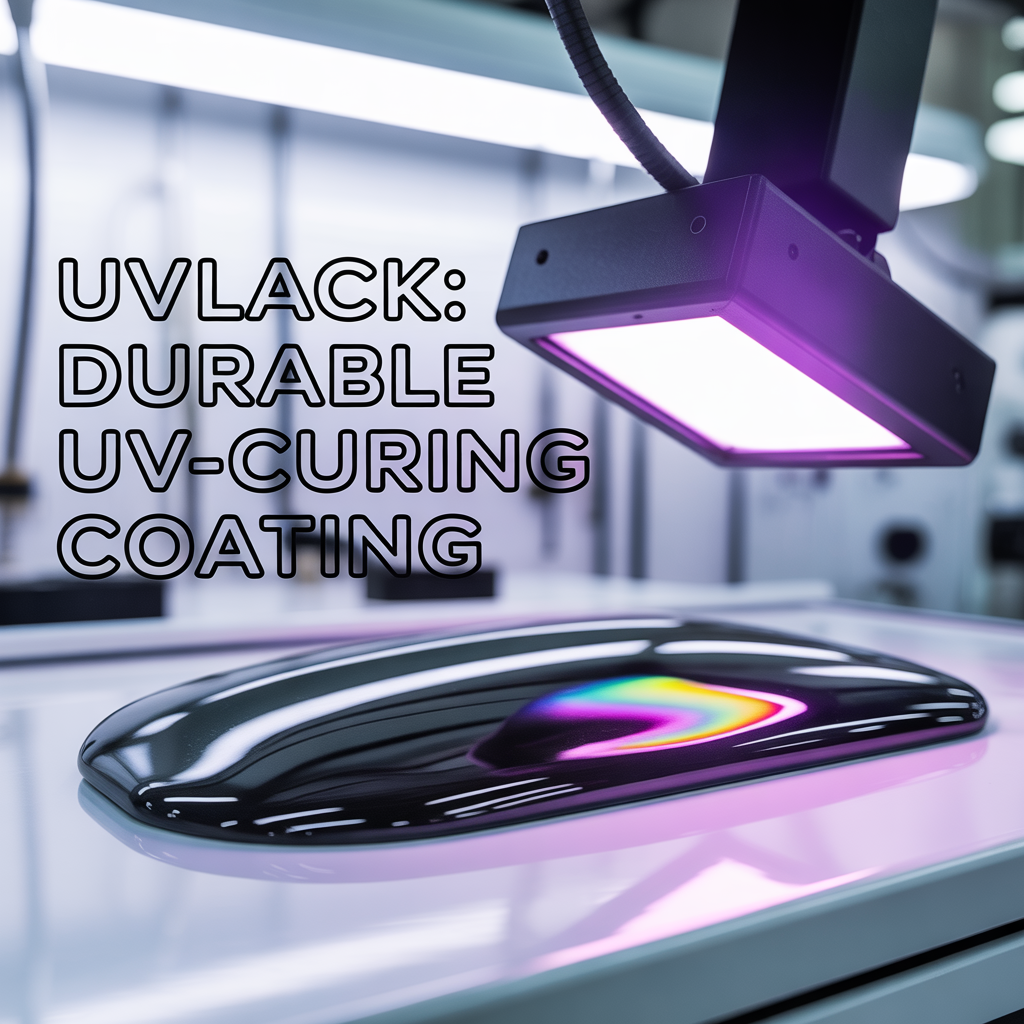

In today’s world, the demand for high-quality, long-lasting coatings has never been higher. Whether in furniture manufacturing, electronics, or nail art, the need for a finish that is both durable and visually appealing is crucial. This is where Uvlack, a UV-curing lacquer or coating, comes into play. Known for its rapid curing under ultraviolet (UV) light, Uvlack has become a go-to solution for industries seeking a glossy, hard-wearing surface.

What is Uvlack?

Uvlack is a specialized coating that hardens almost instantly when exposed to ultraviolet light. Unlike traditional coatings that may require hours or even days to dry, Uvlack undergoes a chemical reaction when UV light strikes it, forming a robust and glossy layer. This unique property makes it particularly valuable in applications where time efficiency, durability, and aesthetic quality are essential.

The term “Uvlack” can refer to two primary applications: industrial coatings and beauty products. In industrial contexts, Uvlack is used on materials such as wood, metal, glass, and plastic to provide a durable, high-gloss finish. In beauty, particularly in nail care, Uvlack refers to UV gel nail polish that cures under a UV lamp, resulting in a manicure that is long-lasting, chip-resistant, and shiny.

How Does Uvlack Work?

The magic behind Uvlack lies in UV-curing technology. Uvlack contains photoinitiators, compounds that react when exposed to ultraviolet light. When the coating is applied to a surface and illuminated with UV light, these photoinitiators trigger a polymerization reaction. This reaction rapidly converts the liquid lacquer into a solid film.

The benefits of this process are significant:

-

Speed: Unlike traditional drying methods, UV curing takes just seconds to minutes.

-

Durability: The resulting film is tough, resistant to scratches, chemicals, and wear.

-

Gloss and Clarity: Uvlack produces a high-gloss finish that enhances the visual appeal of the coated surface.

-

Environmental Efficiency: Many Uvlack formulations are low in volatile organic compounds (VOCs), making them safer for both the environment and the user.

Applications of Uvlack

1. Industrial Use

Uvlack has widespread use in industrial and manufacturing sectors. Its ability to provide a hard, durable surface makes it ideal for protecting materials such as:

-

Wood: Furniture, flooring, and decorative items benefit from Uvlack’s scratch resistance and glossy finish.

-

Metal: Uvlack is used in automotive and electronics industries to coat metal surfaces, preventing corrosion while improving aesthetics.

-

Plastic: Plastic components in electronics, appliances, and packaging can be coated with Uvlack for durability and shine.

-

Glass: UV-curable coatings are applied to glass surfaces for scratch resistance and decorative effects.

The speed of UV curing reduces production time and increases efficiency, making Uvlack a cost-effective choice for high-volume manufacturing.

2. Nail Care

In the beauty industry, Uvlack has revolutionized nail care through UV gel nail polish. Unlike traditional nail polish that dries slowly and chips easily, Uvlack-based gels cure quickly under a UV lamp. This results in:

-

Long-lasting manicures

-

A high-gloss finish that maintains its shine for weeks

-

Increased resistance to chipping and cracking

-

Easy layering for creative nail designs

For salons and individual users, Uvlack offers both convenience and professional-quality results.

Advantages of Uvlack

The popularity of Uvlack can be attributed to its numerous advantages:

-

Rapid Curing – UV light transforms the liquid lacquer into a solid coating in seconds, reducing downtime in production and salon settings.

-

Exceptional Durability – Once cured, Uvlack forms a hard, protective layer that resists scratches, chemicals, and daily wear.

-

Glossy Finish – Uvlack produces a visually appealing, mirror-like shine that enhances the aesthetics of any surface.

-

Versatility – Applicable on wood, metal, plastic, glass, and even nails, Uvlack is suitable for a wide range of industries.

-

Environmentally Friendly – Many modern Uvlack formulations contain low levels of VOCs, minimizing harmful emissions.

-

Customizability – Uvlack can be pigmented, tinted, or layered to achieve various visual effects, from opaque coatings to clear protective layers.

Challenges and Considerations

While Uvlack offers many benefits, there are some considerations to keep in mind:

-

Equipment Requirement – UV curing requires a UV light source, which may involve an initial investment in lamps or curing units.

-

Surface Preparation – Proper surface cleaning and preparation are essential to ensure adhesion and prevent defects.

-

Formulation Sensitivity – UV-curable coatings may require careful handling to avoid premature exposure to light, which could trigger partial curing.

Despite these considerations, the benefits of Uvlack often outweigh the drawbacks, making it a preferred solution for both industrial and beauty applications.

Future of Uvlack

The future of Uvlack is promising, as industries continue to prioritize efficiency, durability, and eco-friendliness. Innovations in UV-curable chemistry are leading to coatings that are more flexible, harder, and even more environmentally sustainable. In nail care, trends toward safer, non-toxic gel formulations are driving further growth in the Uvlack segment.

Researchers are also exploring new applications, such as UV-cured 3D printing resins, advanced electronics coatings, and protective layers for solar panels. With ongoing advancements, Uvlack is set to become an integral part of manufacturing, design, and beauty industries for years to come.

Conclusinhon

Uvlack: Durable UV-Curing Coating represents a revolutionary approach to surface protection and finishing. Its unique ability to cure instantly under UV light, combined with exceptional durability and glossy appearance, makes it a versatile solution across multiple industries. From industrial coatings on wood, metal, and plastic to high-quality UV gel nail polish, Uvlack delivers speed, beauty, and longevity.

As technology continues to advance, Uvlack is likely to see even broader applications, reinforcing its status as a cutting-edge coating solution. Whether you are a manufacturer seeking efficiency and protection, or a beauty enthusiast aiming for a perfect manicure, Uvlack provides a reliable, high-performance finish that stands the test of time.